Presses | Bucher Vaslin

DESTEMMERS & CRUSHERS TRANSFER SORTING PRESSING FILTRATION BOTTLING & LABELLING PUMPS USED EQUIPMENT

Pressing is a crucial and indispensable stage in the winemaking process. A quality pressing consists in extracting as much juice, with the best quality, in the least amount of time, with minimal pressure and crumblings.

Bucher Vaslin: Details make the difference

High quality membranes: Bisphenol A (BPA) free and Phthalate free, High temperature resistance: -5°C to +70°C, Fully manufactured in Bucher Vaslin and fixed to the tank by a particular system (Bucher patent) with no perforation to ensure tightness and durability.

Exclusive dejuicing channels: Large draining surface composed of perforated, self cleaning and non-corrosive channels (Bucher patent), Electro-polishing of slotted channels to facilitate cleaning, Swiveling drainage elements (Bucher Vaslin patent) facilitate the press cleaning and ensure optimized hygiene.

With the Winect® application, you can get information anytime on your Smartphone about the pressing in progress: program in progress, remaining time, pressure, flow rate… Thanks to this remote support service, a diagnosis is immediately given by a qualified technician for a greater peace of mind

Organ program: automatic, self-decisional, intelligent pressing program with real-time adjustment

Inertys options

inert gas pressing - BUCHER Inertys

SELF-DECISIONAL pressing - Organ

Bucher Organ the automatic self- decisional making process for running Bucher XPlus IT and Xpert IT presses. Organ is a tanks management method based on the measurement of the juice drain-off rate in the press juice bin. These measurements are transmitted to the software for the management of draining and pressing cycles. Depending on the operator’s targets, Organ analyzes the reaction of grapes and adjusts programming on an ongoing basis as follows: the percentage of juice extraction, the maximal duration of pressing, and type of grapes/varieties. Bucher Organ leaves the operator free from any constraints related to a complicated programming due to pressure, pressure keeping-up, number of tank rotations…

The Bucher Vaslin process of pressing under controlled atmosphere, innovating and patented, guarantees 100% of the pressed juices extracted without oxidation. This thanks to a permanent operation in closed loop. The gas used is recycled by means of a flexible reserve, and can thus serve several times. The utilization costs are weak. The process is entirely automatic.

Available on :

• Bucher XPlus 22 to 80

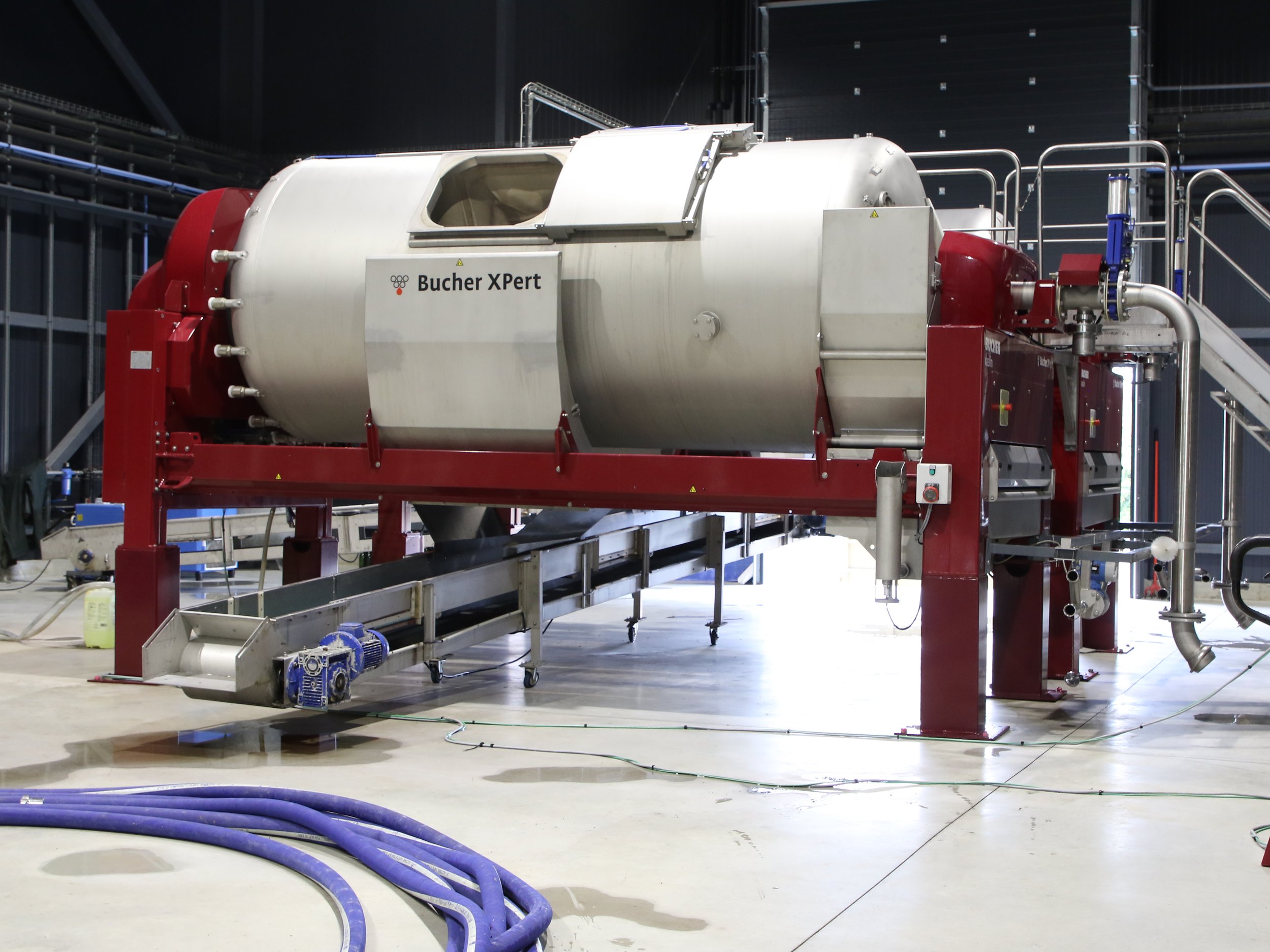

• Bucher XPert 100 to 450